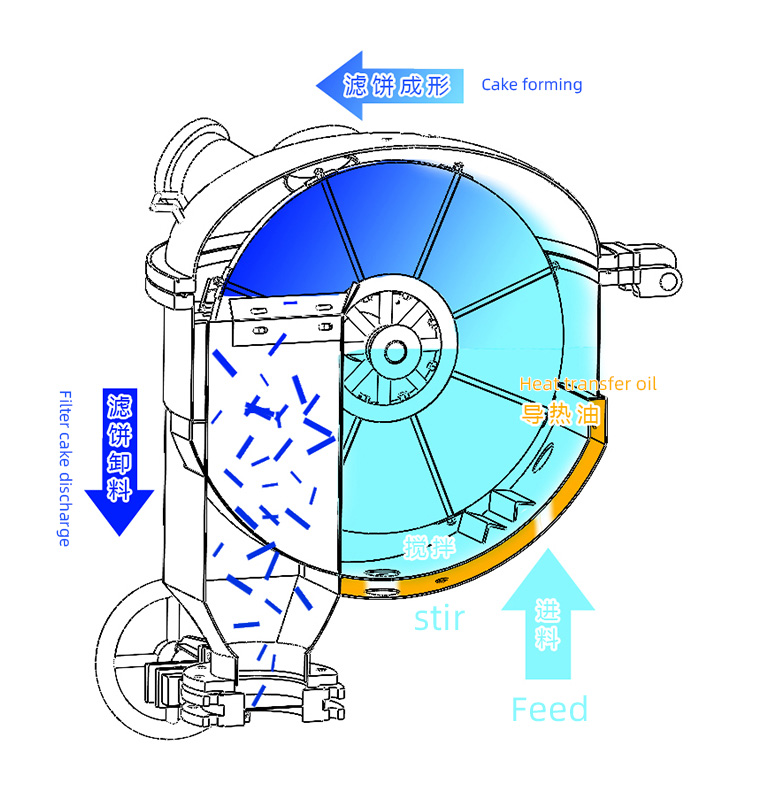

CF disc ceramic membrane filter

The Fude disc ceramic membrane filter has been innovated to achieve continuous filtration. The ceramic membrane used in the device has a fan-shaped appearance, with several liquid flow channels inside, and the film layer is applied to the surface. The liquid flow path is connected with the device main shaft and the filtrate tank. It can meet the challenges of today's solid-liquid separation of ultrafine materials.

The new nanofilter-grade ceramic plate film has been replaced, and the filter plate has a higher density, which is suitable for the filtration of small particles. Can achieve microfiltration: 0.2um, 0.5um, 2.0um ultrafiltration: 60nm, 100nm, 200nm filtration.