Equipment selection

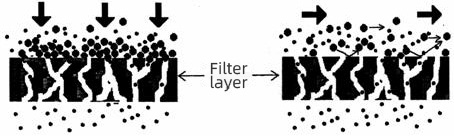

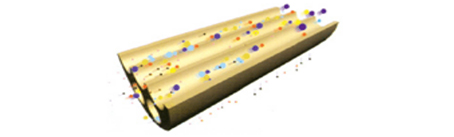

Ceramic membrane is a kind of precision filter material with porous structure, which is sintered at high temperature by alumina, titanium oxide, zirconia, etc. The porous support layer, transition layer and microporous membrane layer are asymmetrical distribution, and the filtration accuracy covers microfiltration, ultrafiltration and even nanofiltration.

Inorganic ceramic membrane pipe has the advantages of high temperature resistance (multi-channel <150℃, the maximum working temperature of single channel pipe can reach 800 ℃), high pressure resistance (maximum working pressure can reach 16MPa), acid and alkali resistance (PH0 ~ 14), high porosity (35%), uniform aperture, high mechanical strength, long service life, clean, tasteless, non-toxic and so on. Filter pore size up to 1.2, 0.8, 0.2, 0.1μ m, ultrafiltration 50, 30nm,5nm.

|

Section shape

|

|

|

|

|

|

|

|

|

Aperture/interception molecular weight

|

MF:1.2-0.8-0.2-0.1μm UF:50-30nm 100-50-20-5KD NF:1-0.45KD

|

|

Outer diameter mm

|

10

|

30

|

30

|

25

|

30

|

40

|

40

|

|

Channel diameter mm

|

7.0

|

6.0

|

3.8

|

6.0

|

4.0

|

3.6

|

6.0

|

|

Number of channels

|

1

|

7

|

19

|

9

|

19

|

37

|

19

|

|

Length mm

|

1016

|

1016

|

1016

|

1200

|

1016

|

1000

|

1000

|

|

Membrane area m2

|

0.02

|

0.13

|

0.23

|

0.20

|

0.23

|

0.42

|

0.38

|

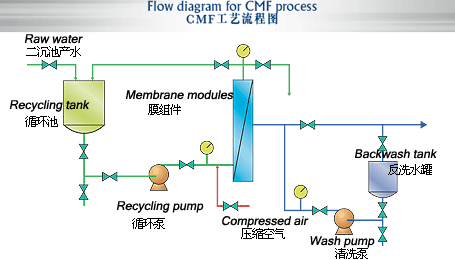

Membrane housing assembly

The membrane component is a pressure shell for assembling ceramic membrane components. According to the needs of industrial production, the ceramic membrane components with different outer diameters and different areas can be centrally loaded through different specifications of membrane component shells. The filling film area of a single film assembly ranges from 0.05 square meters to 20 square meters. The shape design and sealing design of the membrane components are very important to the operation of the ceramic membrane complete system.

Number of filled film elements: 1,3,7,12,19,37,61,99 cores

Matching membrane element length diameter: 250-1200mm/ Outer diameter 25, 30, 40mm

Main material: 304ss, 316L, titanium, polypropylene

Sealing material: EPDM rubber, fluorine rubber, silicone rubber, etc

Interface type: flange, clamp, loose /DN15-400

Standards: iso, din/ Chemical grade, health grade