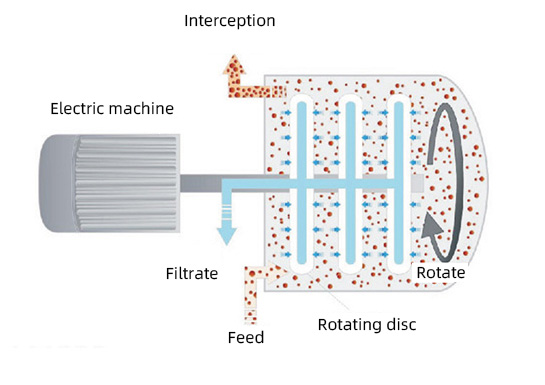

CDC Disc Cross Flow Filter

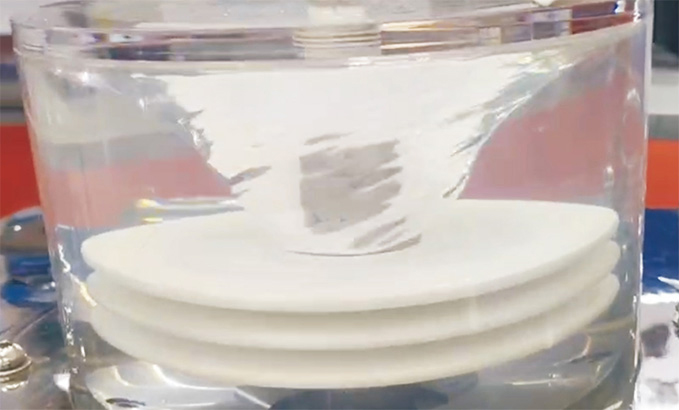

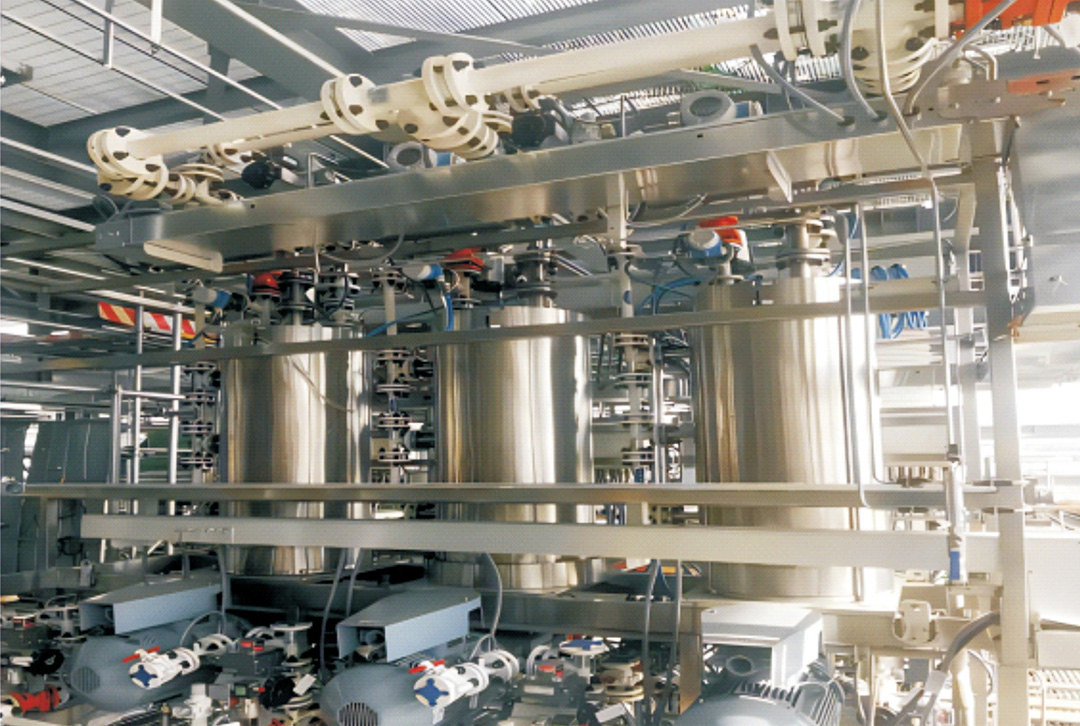

Clarifier, deep-cone thickener, tubular filter, inorganic membrane filter, ceramic flat membrane filter, etc. used in manyindustrial fields such as replacing pigment and chemical industry. The FD CD c disc cross flow filter has been redesignedto meet the challenges of today's solid-liquid separation of ultra-fine materials. The new nanofiltration ceramic platemembrane is replaced, and the filter disc density is higher, which is suitable for the filtration of tiny particles.