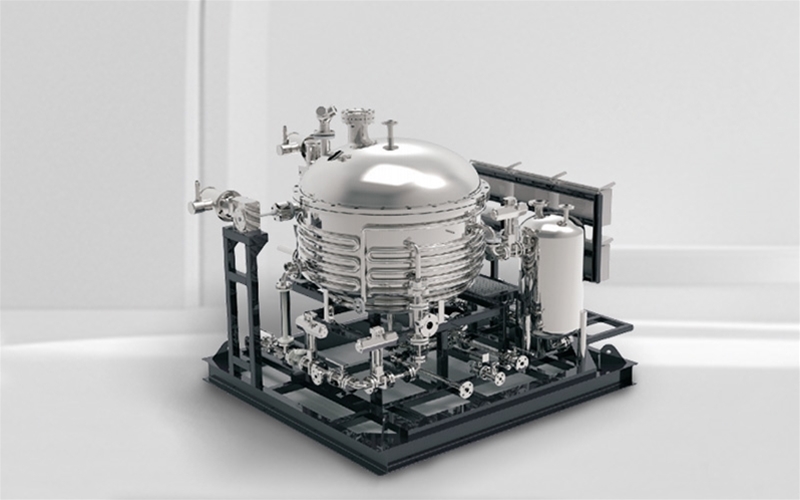

CPF flat ceramic membrane filter

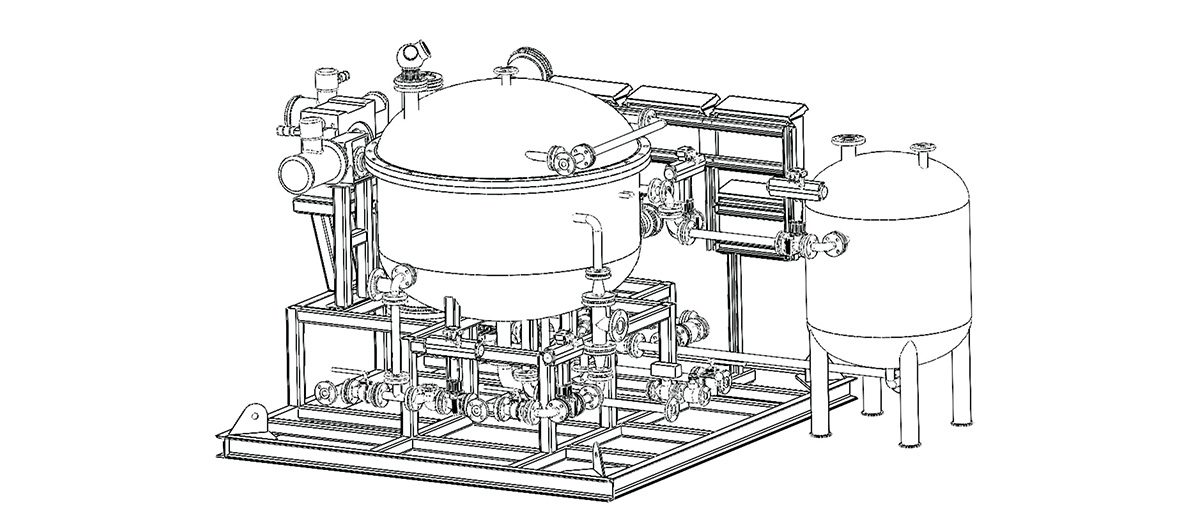

Fude patented technology for nanoscale filtration. It created a new situation of continuous solid-liquid separation filter with nanoscale dead-end filtration. Its development is designed to work with the CDC disc cross-flow filter, although it cannot perform effective washing, but can obtain a high filtration capacity in a very short unit time, itself is a very promising new model.

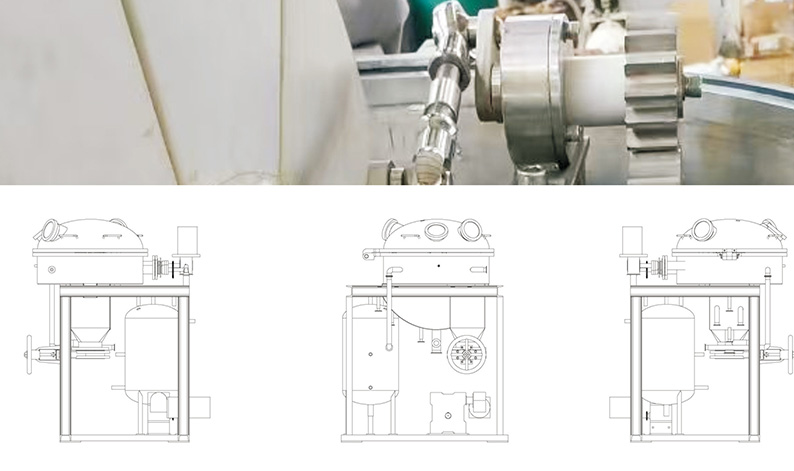

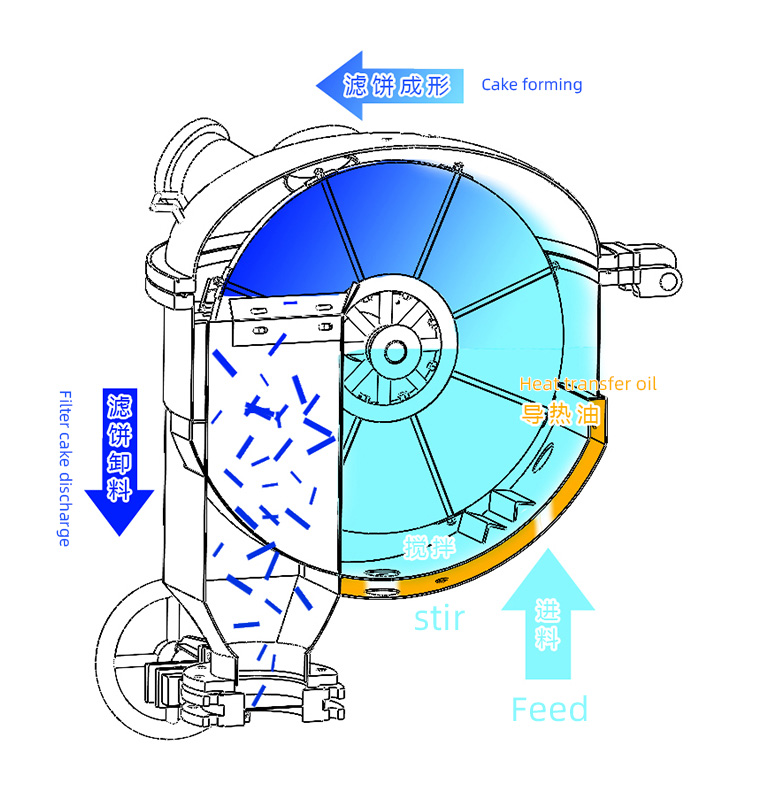

Several nanofilter-grade ceramic membranes are installed on the rotor. After the slurry is injected into the closed slurry tank, the rotor is slowly rotated. At the same time, the filtrate passes through the membrane and enters the filtrate tank from the distributing valve due to vacuum suction. The material flows perpendicular to the film surface under a certain driving force. It can maintain a stable filtration state for a long time.