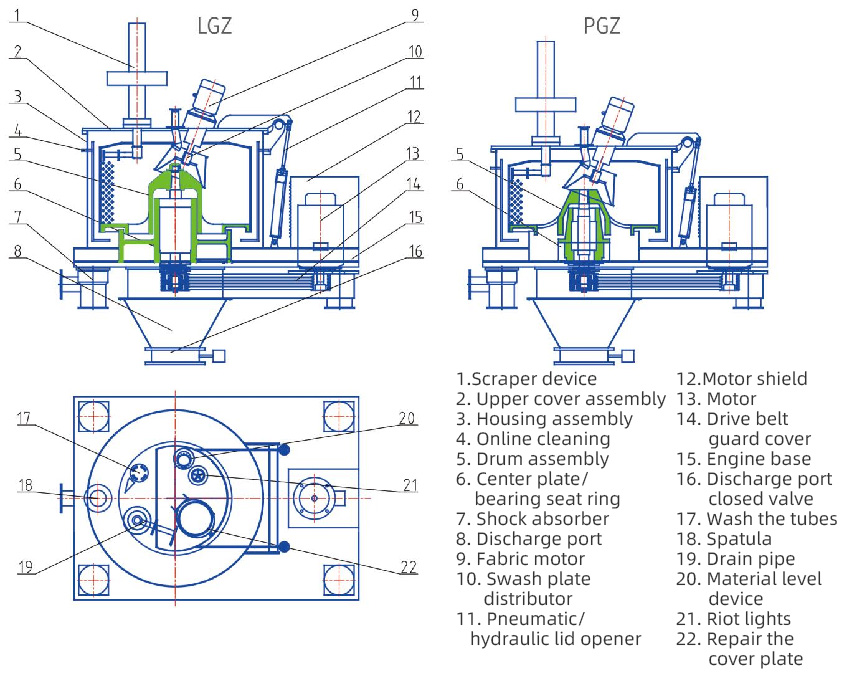

LGZ type centrifuge

LGZ centrifuge can set the program according to the requirements of use, and automatically complete the feeding, separation and washing, dehydration, unloading and other processes, which can achieve far and close operation. With a high degree of automation, large processing capacity, good separation effect, canceling the traditional hanging leg, the use of flat weight and high viscosity damping agent vibration absorber vibration, no foundation installation.

Be widely used in

It is suitable for separating suspension containing solid phase particle size greater than 0.05mm, especially suitable for material separation not accessible to personnel, and suitable for food, pharmaceutical, chemical, national defense and other industries.