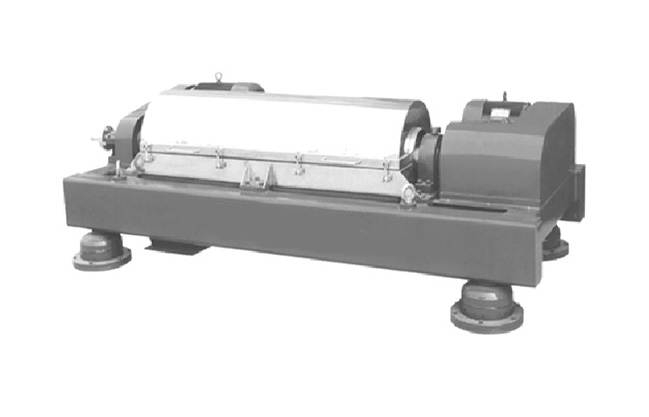

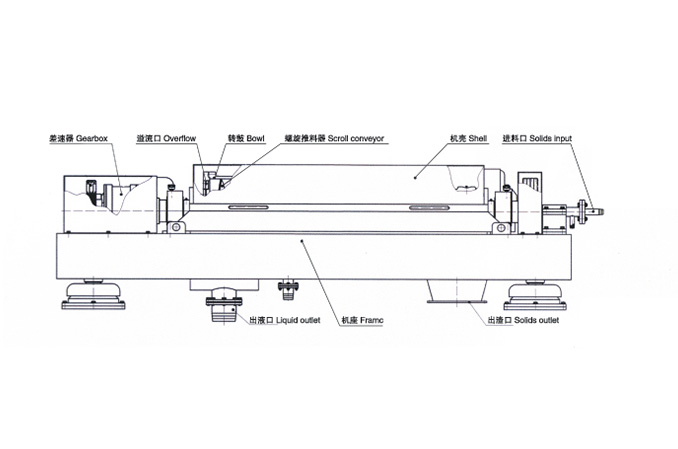

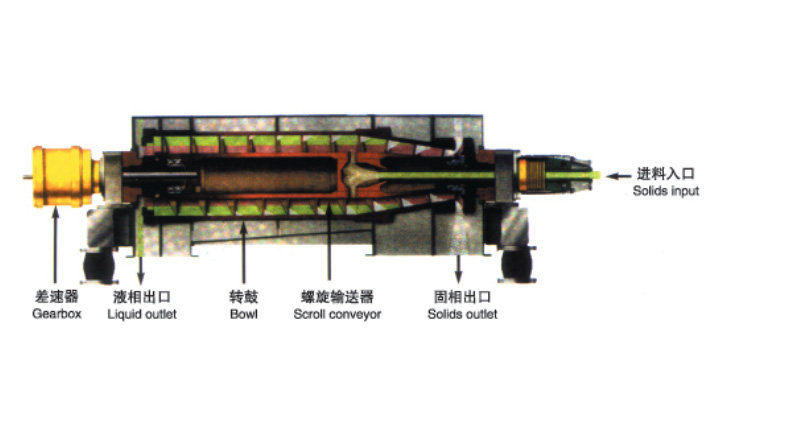

LW series horizontal screw discharge sedimentation centrifuge

After changing the technical parameters, it can be used to separate materials with different requirements, with strong adaptability to material separation, large processing capacity, continuous operation, simple operation, low operating costs, small footprint and other significant advantages, suitable for separating the suspension containing solid particles ≥0.005mm, the concentration range of 2-40%.