PBF mobile disc vacuum filter

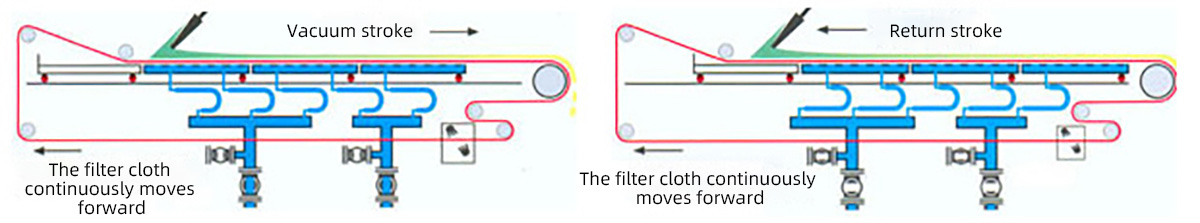

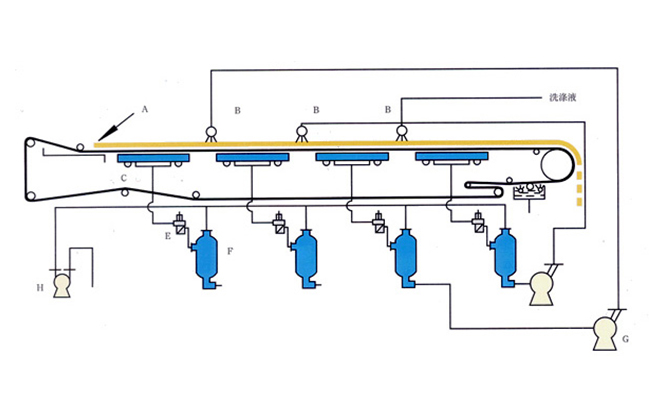

The moving disc vacuum belt filter is a traditional filtration equipment, which uses the filter cloth or filter screen as the medium, so that the slurry is horizontally arranged on the filter medium, and makes full use of the slurry gravity and vacuum suction to achieve solid-liquid separation.

Be applicable to

Materials under a variety of concentration conditions, suitable for thixotropic, washing materials, so it is preferred by many industrial sectors.