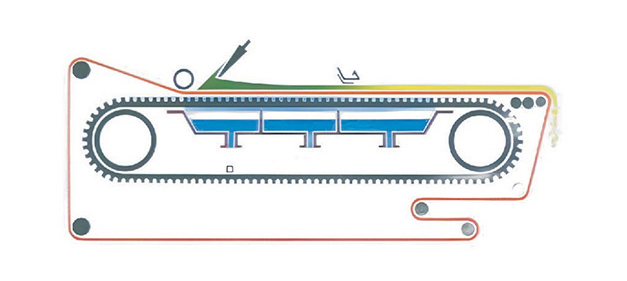

DU Rubber Horizontal Vacuum Belt Filter

The machine relies on vacuum suction to achieve continuous operation of filtration equipment, high efficiency, large production capacity, good washing effect, simple operation, low maintenance costs.

Be widely used in

Metallurgy, mining, chemical industry, power plant wet flue gas desulfurization, coal chemical industry, paper making, food, pharmaceutical and environmental protection industries.