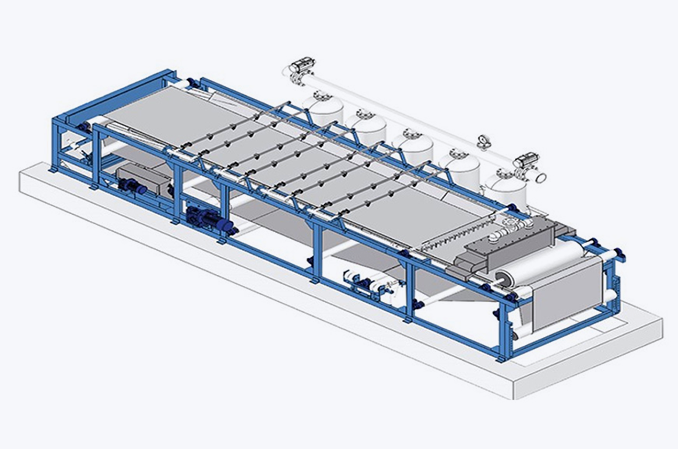

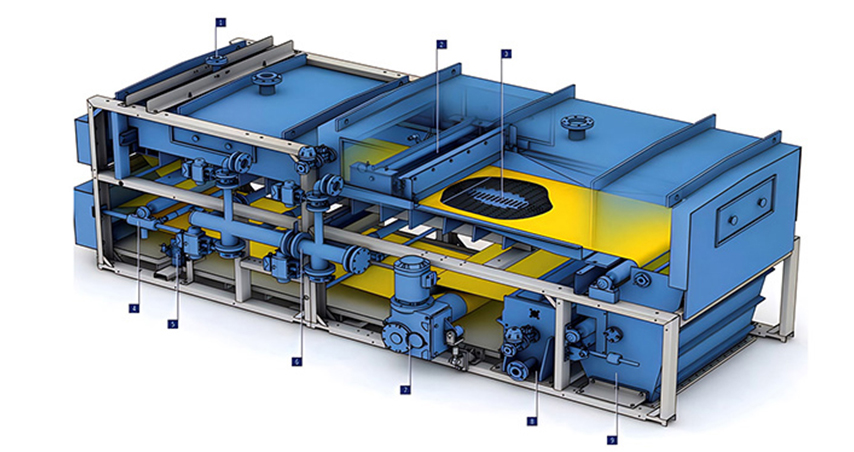

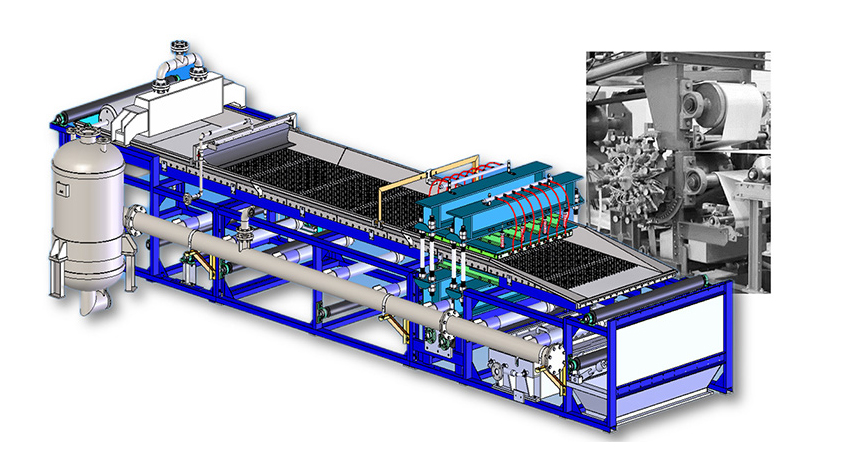

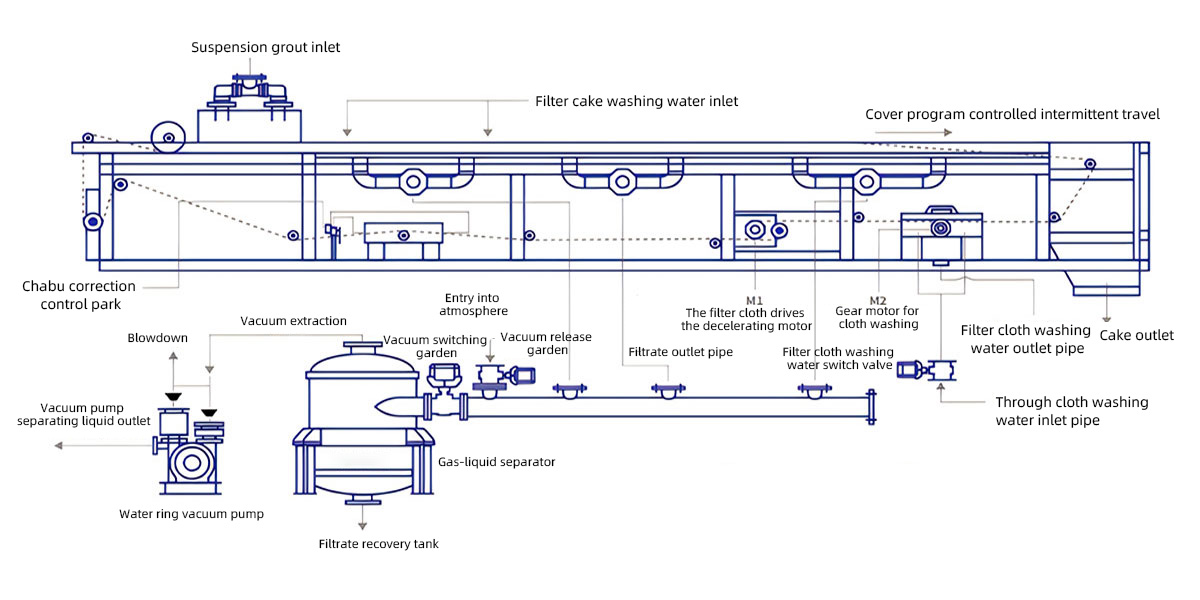

TBV Indexing Belt Vacuum Filter

The filter tape operates in a step-by-step loop. The slurry enters the vacuum plate continuously to form filter cake. At each stop gap, the filtrate is discharged, and then the vacuum stops; The cake continues to flow forward. After the cake is formed, it can be treated by washing (multiple washing and countercurrent washing as needed), pulping, steam, extraction, draining, pressing, microwave, etc. In this process, filtrate can be collected separately from each vacuum tray and processed without crossing. Finally, the cake is discharged from the discharge roller. The cleaning of the filter cloth is carried out simultaneously during the unloading of the cake.