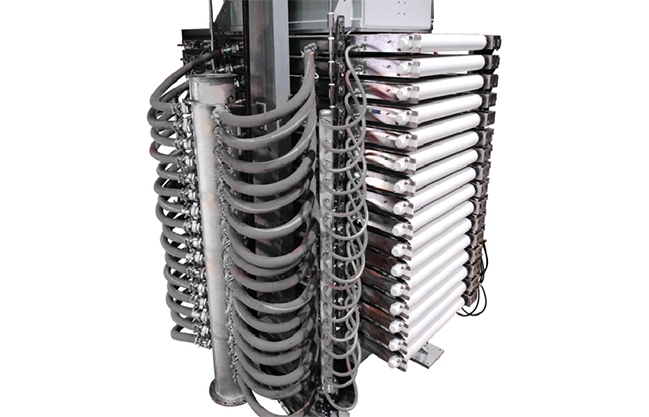

DPF laminated filter press

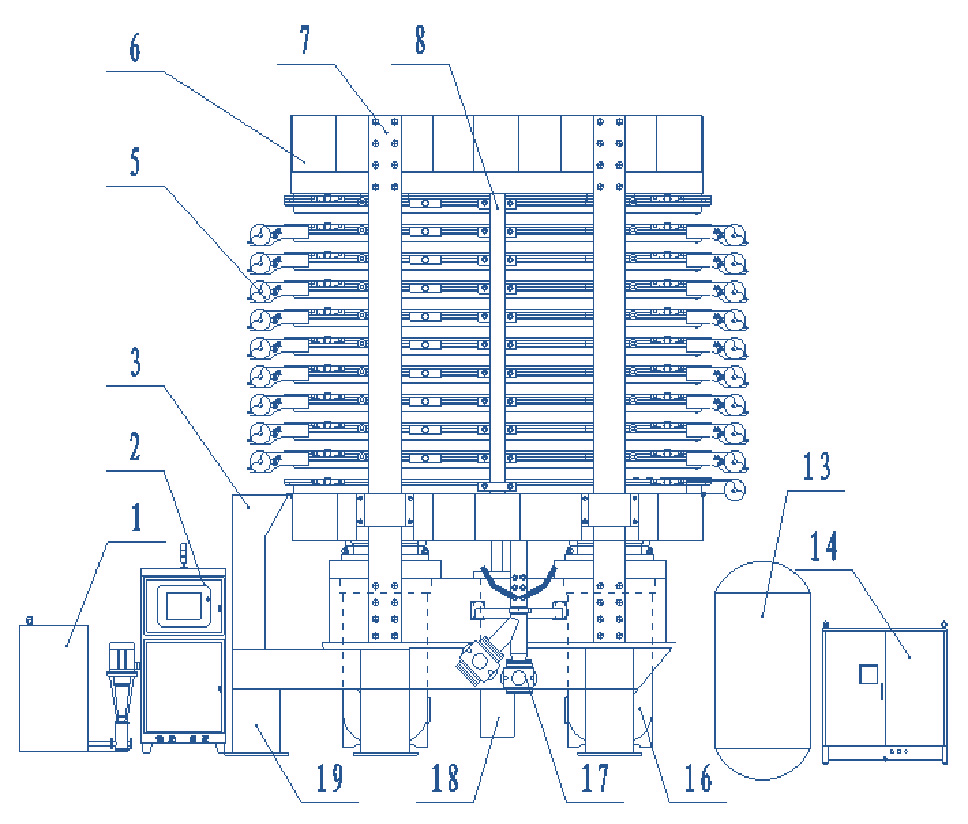

Laminated filter press is a fast opening and closing automatic filter press, which is mainly composed of electrical control system, hydraulic control system and main engine.

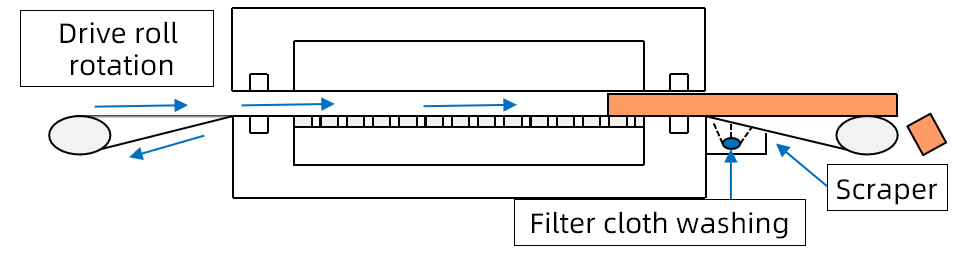

When the equipment is working, the main hydraulic cylinder first pushes the upper pressure plate down, and the filter plate groups of the filter press press each other, so that the closed filter chamber is formed between the adjacent filter plates. The equipment circulates each layer of filter cloth, which can be discharged on one side.

Be widely used in

Dewatering of various mine concentrates and tailings; Smelting, chemical industry oxide, electrolytic slag, leaching slag, slag dehydration and environmental protection sewage sludge waste acid treatment.