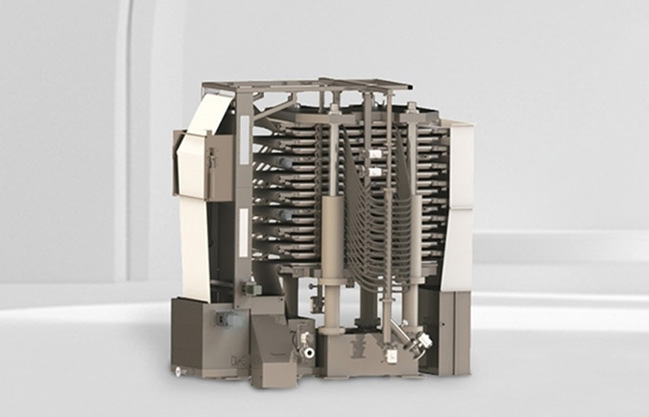

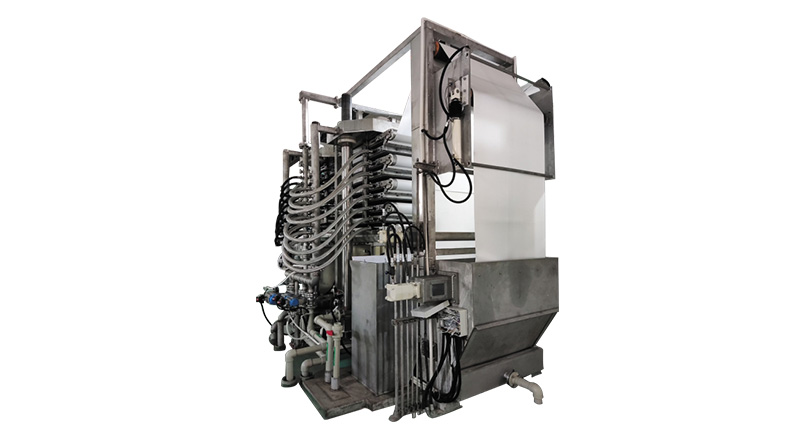

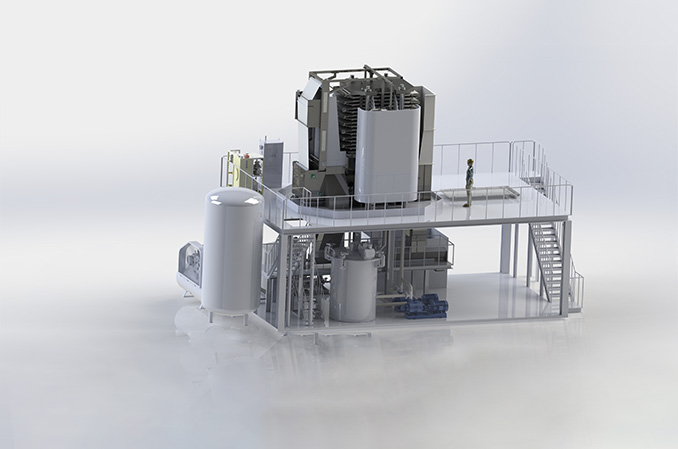

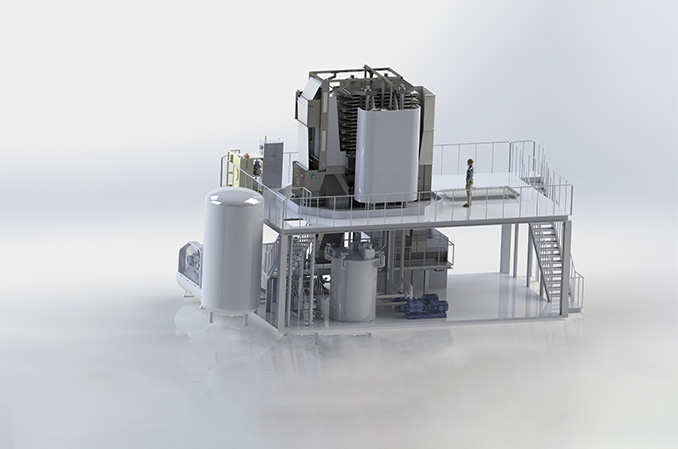

TPF Intelligent Vertical Tower Filter Press

With the action of pump pressure, material force and air or water pressure, the machine forms pressure difference onboth sides of the filter cloth, so as to realize high-efficiency solid-liquid separation. It is a high-tech filter productintegrating mechanical, servo hydraulic and intelligent control.

Technical Advantages

It is the first in China, with automatic intelligent operation, and the water content of filter press can reach the lowest among various models in the market. Effectively solve the problems of poor field working conditions, high failure rate and complex maintenance of traditional models.

Innovation: automatic intelligent operation, press filtration water content can be particularly low in the current market models. It effectively solves the problems of poor working conditions, high failure rate and complex maintenance of traditional models. It includes a complete industrial control system, data upload to the cloud, remote control, fault warning self-overhaul, etc., which is more intelligent than ordinary solid-liquid separation equipment. Through the cooperation of the control system and the cloud database, according to the data collected by various sensors, problems can be found earlier than manual. At the same time, it can also better monitor the status of materials in each period and automatically adjust to a more suitable operating cycle or notify relevant personnel and equipment manufacturers in time. Through different sensors, the operation of the equipment can be visualized, and the cause of the problem can be more clearly understood through data comparison and on-site detection, which greatly reduces the maintenance time and avoids a series of problems caused by production line shutdown, so as to stop and repair.